Sustainable quality Made by Brock

As a manufacturer of high-quality light alloy wheels, we bear responsibility—towards the environment, our employees, and future generations. For us, sustainability means making mobility more efficient, resource-friendly, and conscious, without compromising on quality and safety.

Climate neutrality

We are continuously reducing our environmental footprint through better energy sources, optimized processes, and sustainable logistics—making our production more climate-friendly year after year.

Clean energy

Our production site consistently relies on renewable energy. In addition, we are expanding our own power generation to become even more independent of fossil fuels.

Biodiversity

We strengthen the natural environment around our site with targeted environmental projects. Tree planting promotes biodiversity, improves the local climate, and makes a long-term contribution to environmental protection.

Sustainable mobility

Most of our internal transport vehicles are already electric. Our goal: to make mobility at our site completely emission-free – for a clean and efficient flow of materials.

Industrial efficiency

We reduce resource consumption and waste through modern technologies and continuous improvements. In this way, we combine efficient production with responsible action and sustainable progress.

Picture by Damien Dan on UnsplashThe future needs responsibility.

A key component of our approach is the efficient use of raw materials. Any excess material generated during production is completely recycled in our in-house recycling process and returned to the cycle. This ensures that aluminum is used optimally and no resources are wasted unnecessarily.

In addition to resource-efficient manufacturing, we place particular emphasis on environmentally friendly packaging solutions. Wherever possible, we use cardboard boxes and packaging materials with a high proportion of recycled fibers. At the same time, we are continuously optimizing our packaging concepts in order to save material, make transport routes more efficient, and reduce CO₂ emissions in logistics.

Quality through efficiency

For Brock Alloy Wheels, sustainability also means taking a holistic view of processes:

from energy-efficient production and state-of-the-art quality and testing procedures to safe working conditions and the responsible use of resources.

ESG & CO₂-Management

We pursue a clear ESG approach and reduce our carbon footprint through effective measurement, targeted measures, and continuous optimization at the company and product level.

REACH & GADSL – Supply chain compliance

Our supply chain consistently complies with all REACH and GADSL requirements. We continuously test materials, maintain close contact with suppliers, and provide our customers with transparent information.

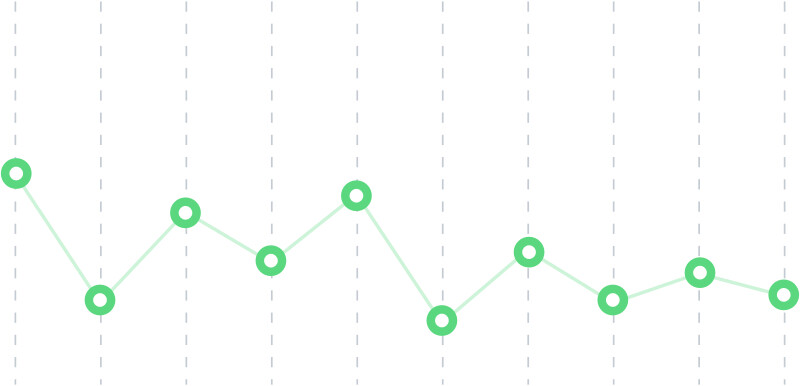

Continuous emission reduction

Sustainable motion

We develop and produce wheels that not only impress with their technical features, but also set standards in terms of energy and material efficiency.

FAQ

What is Brock Alloy Wheels doing to reduce emissions and protect the climate?

We are continuously improving our processes, energy supply, and logistics in order to reduce our carbon footprint. Compared to the previous year, we were able to significantly reduce our emissions.

How does Brock Alloy Wheels use renewable energy?

Our production site operates entirely on certified green electricity. We are also investing in our own solar power systems, which cover a growing proportion of our energy requirements. Our central warehouse is already supplied with solar energy generated in-house.

What measures does Brock Alloy Wheels support in the area of biodiversity?

We actively promote local nature projects around our site. Tree planting strengthens biodiversity, improves air quality, and helps with CO₂ sequestration in the long term.

How sustainable is internal mobility?

The majority of our internal transport vehicles are electric. Our goal is a completely emission-free material flow – supported by renewable energy sources.

How does Brock Alloy Wheels increase efficiency and innovation in production?

We continuously optimize our processes: more efficient compressed air systems, low-temperature curing primers, and heat recovery reduce energy consumption, costs, and CO₂ emissions.